What is a SIPOC Diagram?

→ A SIPOC diagram is a visual tool that is used for the analysis and mapping of the organization’s various processes.

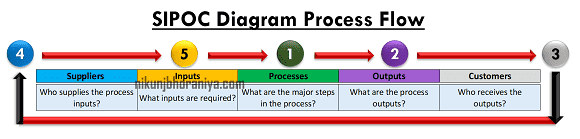

→ The acronym of SIPOC stands for Supplier, Input, Process, Output, and Customer.

→ So with the help of this tool, we can easily analyze the process from the supplier end to the customer end.

→ It is a high-level Process Mapping Tool.

→ It is widely used in the Lean Six Sigma Project.

→ SIPOC_Diagram is very helpful in continuous improvement projects like Lean Six Sigma.

→ Nowadays, This tool is a very famous process improvement tool.

→ This diagram helps us to understand any process.

→ SIPOC_Diagram is often used in the Define phase of the DMAIC Methodology.

→ It helps organizations resolve process-related issues and initiate improvement activities.

→ The Basic SIPOC_Diagram looks as mentioned below.

👉 Get SIPOC Diagram PowerPoint Template Free Download

Meaning of SIPOC

→ The meaning is explained below

→ As we know that the SIPOC stands for Supplier, Input, Process, Output, and Customer. Also, we will understand the meaning of all words

- Supplier – The supplier is the input provider into a process

- Input – The input of the process should be materials, information, and other resources that are needed to complete a process

- Process – A process is a series of interrelated structured steps for getting the desired output. Only, we can say that it converts input into an output

- Outputs – An output is either a product or service that we can get from the process

- Customer – The customer is the user or receiver of the output

SIPOC Diagram Example

→ We will understand the SIPOC_Diagram with the help of an example and a Case Study.

→ Before going forward we will understand how to create the diagram.

👉 Get SIPOC Diagram Excel Template Free Download

How to create a SIPOC Diagram?

→ We will understand the creation of a SIPOC_Diagram in very easy 7 steps

→ Basically, the SIPOC_Diagram is a simple table in which we need to mention process-wise steps that are related to the supplier, input, process, output, and customer.

→ We will refer to the below 7 steps for a better understanding of the SIPOC_Diagram.

- Identify the Proces

- Define the process steps

- List down the Outputs

- Identify the Customers

- Determine the Inputs required for the process

- Identify the Suppliers

- Validate the diagram

Step 01: Identify the process

→ Identify the_process for which we need to create the SIPOC_Diagram.

→ Also, communicate with the project team because it must require that all team members have clarity about the_process.

Example:

→ In this example, we will understand the SIPOC_Diagram for the "Corrective Action Process"

→ The process_steps are mentioned below that we will mention in vertical sequence as mentioned in the picture.

- Problem Confirmation

- Containment Actions

- Root Cause Investigation

- Corrective Action Implementation

- Verification & Closure

Step 02: Define the Process Steps

→ The Process is a set or sequence of activities.

→ We will consider the process_sequence as (1) Process, (2) Output, (3) Customer, (4) Supplier, and (5) Input.

→ The template of the SIPOC_Diagram process_sequence is mentioned below

Step 03: List down the Outputs

→ Outputs are the products or services that we need to deliver to customers.

→ In this step, we need to mention the output of the process steps.

→ That we can see into the picture under the output column.

Step 04: Identify the Customers

→ In easy language, we can understand the customers as the consumer of the outputs that are produced by the process.

→ Customer may be internal stakeholder, or they may be the outsider of the organization.

→ The customer for the different processes and different outputs is different that we need to identify and need to mention in the customer column.

→ So we have identified different customers for the different processes and outputs that we can easily see in the above picture.

Step 05: Determine the Inputs required for the process

→ Input defines the material or information used by the process to produce the output.

→ Input is a very important part of the process because the variation in input might create a big impact on output.

→ We can easily understand the correlation of the Inputs with the process steps from the above picture.

Step 06: Identify the Suppliers

→ Suppliers are the provider of inputs to the process.

→ The supplier may be an internal stakeholder or maybe an outsider of the organization.

Step 07: Validate the diagram

→ Once the SIPOC_Diagram completes then we need to share it with all relevant stakeholders for validation.

→ If any modification requires then the basis of the team discussion the changes will be applied.

Benefits of SIPOC Diagram

→ It helps to define the new processes

→ It provides a project overview for any process to all the stakeholders

→ SIPOC Diagram helps for problem-solving and Improvement Projects like Six Sigma Projects

→ It is a high-level Process Mapping tool

→ Ensures all the stakeholders are on the same page

Nice content. Thank You!

ReplyDeleteYou are most welcome!!!

DeletePost a Comment