How to Implement TPM (Total Productive Maintenance)?

Introduction of TPM

→ TPM stands for "Total Productive Maintenance" and its a strong relationship between Productivity and Maintenance.

→ It tells us about the care of our equipment can give us good productivity.

→ TPM is all about ownership and continual improvement.

→ It empowers the machine operator to maintain and operate the machine in good condition.

→ Total Productive Maintenance helps organizations for Effective and Efficient Productivity.

→ The goal of TPM is zero accidents, zero breakdowns, and zero defects.

→ There is a very tough competition in today's scenario and it is increasing day by day.

→ So customers focus on Product Quality, Delivery Time, and Cost of Product.

→ To fulfill customer's requirements we need to implement various systems at our site also.

→ Refer to this article for Detailed Presentation of Eight Pillars of Total Productive Maintenance.

→ TPM focuses on improve planning and scheduling.

→ Also, focus on different wasteful activities like 16 Major Losses of Production and 6 Big Losses of OEE.

→ Visit this article: 6 Big Losses of OEE that will help us to improve our productivity.

→ Also, visit this article: 16 Major Losses of Production that will help us to improve profitability.

→ Also, refer to this article: Complete Overview of TPM Explained with Complete Details

Benefits of TPM (Total Productive Maintenance)

→ The major benefits are mentioned below:

→ Increase Productivity and OEE (Overall Equipment Efficiency).

→ Reduce customer complaints.

→ Reduce production cost.

→ Increase customer satisfaction by delivering the right Quality Product, at right time with the right cost-benefit of the customer.

→ Reduce accidents.

→ Morale and Motivation improve an employee's attitude change of operator from "We operate you maintain" to "We operate we maintain".

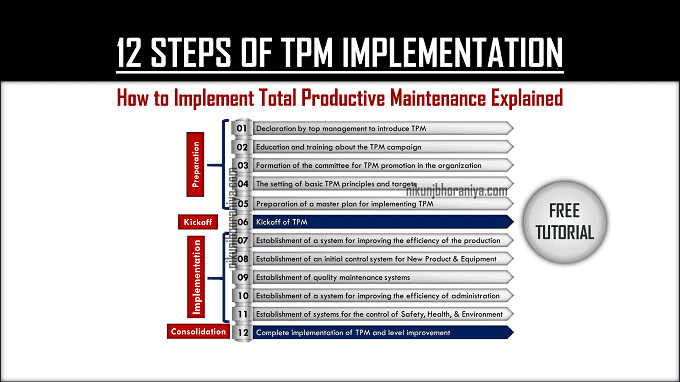

12 Steps of TPM Implementation

→ 12 Steps for Implementation TPM are mentioned below.

- Declaration by top management to introduce TPM

- Education and training about the TPM campaign

- Formation of the committee for TPM promotion in the organization

- The setting of basic TPM principles and targets

- Preparation of a master plan for implementing TPM

- Kickoff of TPM

- Establishment of a system for improving the efficiency of the production

- Establishment of an initial control system for new product and new equipment

- Establishment of quality maintenance systems

- Establishment of a system for improving the efficiency of administration and other departments

- Establishment of systems for the control of safety, health, and the environment

- Complete implementation of TPM and level improvement

Step 1: Declaration by top management to introduce TPM

→ The declaration of the top management about the implementation of TPM in the the organization should be communicated across the organization by a common communication medium.

→ The common communication medium may be notice board, email communication, or internal newsletter.

Step 2: Education and training about the TPM

→ TPM training needs to provide to all employees of the organization.

→ As per the grade and responsibility, the training course needs to design and training should be given.

→ We can give training in any medium like classroom training, virtual training, video lecture, etc.

Step 3: Formation of the committee for TPM promotion in the organization

→ The committees and specialized subcommittees need to be formed for the promotion of the TPM within the organization.

→ The promotion activity can be done with the help of various publications like newsletters, articles, videos, posters, etc.

Step 4: Setting of basic TPM principles and targets

→ Business objectives, benchmarks, and targets need to decide for this improvement journey.

→ As per the current scenarios we need to establish the baseline data for all the organizational KPIs.

→ The setting of SMART goals is: Specific, Measurable, Attainable/Achievable, Realistic, and Time-based.

Step 5: Preparation of a master plan for implementing TPM

→ Prepare the master plan for TPM implementation and also mention the target date and responsibilities.

→ Generally, the time period should be around 3 years but finally, it is decided by the organization.

→ The basis of the master plan, formulate the annual, quarterly, and monthly planning.

Step 6: Kickoff of TPM

→ The top management publically announces the implementation of TPM within the organization.

→ Also communicate the same to various stakeholders like customers, vendors, and various statutory and regulatory bodies.

→ Also, various stakeholders are invited during the kickoff meeting.

→ Total Productive Maintenance implementation activity starts from this step.

Step 7: Establishment of a system for improving the efficiency of the production

→ This step is related to improve the efficiency and effectiveness of the production.

→ For improving productivity and production efficiency we need to implement various 4 pillars of TPM at the production shop floor in this step.

- Kobetsu-Kaizen (Focused Improvement)

- Jishu-Hozen (Autonomous Maintenance)

- Planned Maintenance

- Training & Education Pillar

(A). Implementation of Kobetsu-Kaizen or we can say that Focused Improvement.

→ In these pillars, the project team initiate various activities and workshop of small-group activities that are related to small improvements at production floor.

(B). Implementation of Jishu-Hozen (Autonomous Maintenance) pillars

→ Implement the 7 Step method of Jishu Hozen (Autonomous Maintenance).

→ Develop an autonomous maintenance program for operators.

(C). Implementation of Planned Maintenance pillars

→ Implement the various maintenance practices like corrective maintenance, periodic maintenance, predictive maintenance, etc.

→ Develop a Preventive Maintenance plan for eliminating breakdowns of equipment.

→ It will help us to maintain zero breakdowns.

(D). Implementation of Training & Education Pillar

→ Give train to all team members about the various pillars, skills, and activities.

Step 8: Establishment of an initial control system for new product and new equipment

→ In this step, we need to implement an early equipment management pillar for new product and equipment development.

→ So we can easily get rated output from equipment in a short time period.

Step 9: Establishment of quality maintenance systems

→ In this step, we need to implement the Quality Maintenance pillar.

→ It will help us maintain the zero-defect generation from the machine.

Step 10: Establishment of a system for improving the efficiency of administration

→ In this step, we need to implement the Administration & Officer TPM.

→ This pillar is related to other department's roles for supporting the production department.

Step 11: Establishment of systems for the control of safety, health, and the environment

→ In this step, we need to implement the safety, health, and environment pillar of TPM.

→ This pillar helps to maintain zero accidents.

Step 12: Complete implementation of TPM and level improvement

→ In this step, we should go for the participation of the TPM award.

→ Also, we need to improve our TPM level as per the various levels.

→ Also, we need to take strong targets for next year.

Post a Comment