How to Select the Right Problem Solving Method?

→ As we all know that there are many Problem-Solving Methodologies are

available in daily uses.

→ But sometimes, we have a little bit confused about the selection of the

right problem-solving methodologies.

→ You can use any of the below methodologies as per your requirement for

problem-solving.

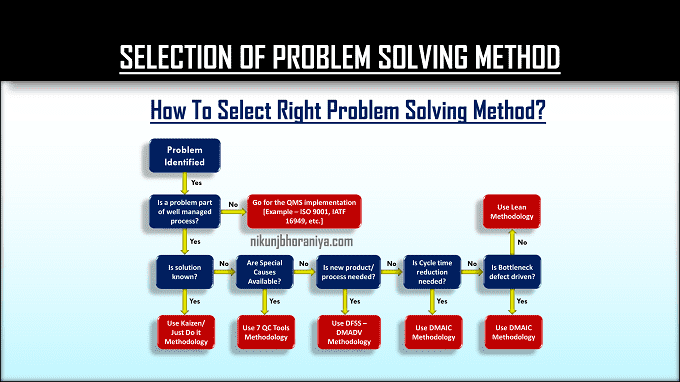

→ For better understanding, you can refer below the diagram for the selection

of the right method.

→ First of all, we need to have an identified problem. Then we can process

further.

➨ Question_01:

→ Now we need to check that the problem is a part of a well-managed process or

not?

→ If it is not a part of a well-managed process then we need to implement any

Quality Management System like ISO 9001 or IATF 16949, etc.

→ For your better understanding, you can refer to this article for detailed knowledge of ISO 9001:2015 and IATF 16949:2016 Explained with Examples.

→ The second possibility is the problem is a part of a well-managed process.

➨ Question_02:

→ Now again we have to ask the question is the solution known?

→ Is the solution is known? then we can directly go on implement the solution just do it or it can be done by kaizen methodology.

→ For better understanding about various types and categories of Kaizen

methodology refer to this article for Case Study of Kaizen Methodology

→ The other possibility is the solution is not known.

➨ Question_03:

→ Now we need to ask are any special causes available?

→ If the answer is yes, we can use the 7QC tool method. It was initiated in

1979 & it is very helpful in identify the special cause related problems.

→ Refer to this article for a Complete understanding of 7 QC Tools explained with Case Study with suitable examples.

→ If the answer is - the special cause is not available then again we need to ask a question.

➨ Question_04:

→ Now we need to check if it requires a new product or process?

→ If a new product/process is required then we can easily go for DFSS.

→ Design for six sigma (DFSS/DMADV) that is one of the popular methodologies of six sigma identified in 1995.

→ Also read, Design for six sigma (DFSS) Methodology with Examples.

→ If it does not require a new product or process. Then again we need to check one more thing that is mentioned below.

➨ Question_05:

→ Is the problem is related to cycle time reduction?

→ If the answer is no then we can directly go for the DMAIC method for six sigma.

→ Also read, DMAIC Methodology Explained with Examples and Case Study.

→ If the answer is yes, we have another question that is mentioned below.

➨ Question_06:

→ The last but not least question is bottleneck defect driven?

→ If the answer is yes then also we can continue to use DMAIC Method.

→ If the answer is no we should use Lean Methodology.

👉 See Also:

Thank you. A valuable overview. For question 5, in the diagram, the answer for both questions are "No". Is it correct to say, it should be "Yes" for the arrow going to Question 6.

ReplyDeleteThank you for your valuable input. We have updated.

DeleteVery usefull /

ReplyDeleteThanks and happy learning

DeletePost a Comment