What is Poka-yoke?

→ Poka-yoke means "error proofing" or "mistake-proofing". It came from the word "Poka" which means "mistake" and "Yokeru" which means "to avoid" and it is a Japanese term.→ It is any mechanism in any process that helps for "mistake-proofing" or "error-proofing".

→ We can eliminate product defects by preventing it, correcting it, or detecting is as they occur.

→ It is one of the Lean Manufacturing Tools

→ This concept was adopted, by Shigeo Shingo as part of the Toyota Production System.

→ Shigeo Shingo used the word "Poka_yoke" in the 1960s for the prevention of human error during industrial process design.

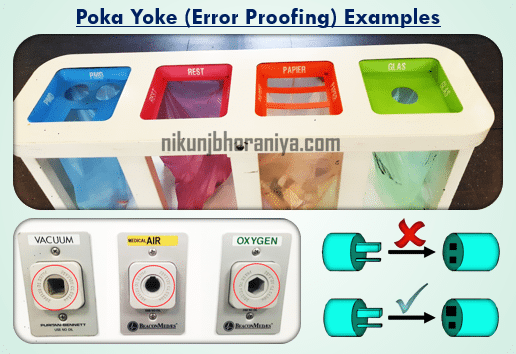

Poka-yoke Examples

→ A simple example is when we start a car having a manual gearbox, we must have to press on the clutch pedal before starting.→ This prevents us against the unintended movement or jerk of the car during the starting

→ Seat Belt wearing Indicator.

→ Auto-locking of the door at the certain speed of the car.

→ Bar code for correct product identification

How to implement Poka-Yoke in manufacturing?

→ It can be implemented at any step of the manufacturing process.→ We should implement this tool, where the possibility of something can go wrong or an error can be made.

→ It is a part of Lean Manufacturing

Steps of Poka-yoke Implementation:

- Identification Problems

- Prioritize

- Seek root cause

- Find and Implement solutions

- Measure the results

What are the types of poka-yoke?

→ Shigeo Shingo recognized three types for detecting and preventing errors in a process as mentioned below.- Contact Method

- Constant Number (or fixed-value) method

- Sequence (or motion step) method

The contact method:

→ The contact_method identifies defects using a part’s shape, color, size, and other physical attributes.→ It can also include limit switches and proximity sensors.

The constant number (or fixed-value) method:

→ When certain movements are not made then this error-proofing or mistake-proofing tool informs the operator this method is known as the constant number (or fixed-value) method.→ Counters can be used for this at each step of the process as necessary.

The sequence (or motion step) method:

→ This method ensures the sequence fo the process step before moving to the next step.→ This is known as the sequence (or motion step) method.

→ The sequence_method is not allowing the mistake to be made in the first place.

→ Example of sequence_method is color coding and tagging and this parameter are checked at each step before moving forward.

Poka-Yoke Principles

- Quality Processes

- Utilize a Team Environment

- Elimination of Errors

- Eliminate the Root Cause

- Do It Right The First Time

- Eliminate Non-Value Added Decisions and Activity

- Implement a Continual Improvement Approach

→ Make a robust process design for zero defect manufacturing.

[2] Utilize a Team Environment:

→ For any improvement, brainstorm with the teams so we can use their knowledge and experience to implement our improvement.

[3] Elimination of Errors:

→ Use various problem-solving methodologies or techniques for reducing defects and decrease defect to zero.

[4] Eliminate the Root Cause:

→ Eliminate the root cause of any problem by implementing this tool.

[5] Do It Right The First Time:

→ Make the process very effective to perform functions correctly for the first time.

[6] Eliminate Non-Value Added Decisions and Activity:

→ Identify all non-value added decisions and activities and eliminate them.

[7] Implement a Continual Improvement Approach:

→ We can not get 100% result in a single try.

→ So, implement improvement actions immediately and focus on continual improvements so we can get a 100% result.

Six Poka-Yoke Techniques Explained with Examples

- Elimination

- Replacement

- Prevention

- Facilitation

- Detection

- Mitigation

Elimination:

→ Primarily focus on elimination→ In Elimination, we have to eliminate the step that is responsible for the mistake

→ Remove Non-Value Added activities

→ Redesign the product and modification of the process (as applicable)

→ Examples: Replace manual data entry with barcode scanning

Replacement:

→ If elimination is not possible the second option is Replacement.→ In Replacement, we have to replace the step with a more reliable mistake-proof one

→ Automation of repetitive motion activities

→ Examples: Welding Robotics for an automotive manufacturer

Prevention:

→ If the above two methods are not possible then the 3rd option is prevention.→ Change product or process (as applicable) so that mistake is prevented.

→ Prevention is a physical barrier to prevent undesired action.

→ Examples: Safety guards on rides, Plugs for 110V & 220V, Printer cartridges and Go/No Go Gauges, etc...

Facilitation:

→ If the above three methods are not possible then the 4th option is facilitation.→ Facilitation is to help someone to take the right decision.

→ We can facilitate any process or product by visual controls like color coding, labels, lines, and signs, etc...

→ Examples: Warning signs, Checklists, Traffic lane markings, Color-coded parts or tools, etc...

Detection:

→ If the above four methods are not possible then the 5th option is facilitation.→ Detection is to identify or detect the wrong product or process immediately after it happens

→ We can provide detection by Sensors, limit switches, or light sensors

→ Examples: Safety guard limit switches to prevent machine running in an open condition, Computer warning if all information is not filled in

Mitigation:

→ If the above five methods are not possible then the 6th option is mitigation.→ Mitigation is to minimize the effects of mistakes or failures.

→ This method is used when the mistake cannot be eliminated

→ Examples: Personal protective equipment, Airbags in cars, Electrical Fuses, and An eraser on a pencil, etc...

Benefits of poka-yoke implementation:

→ Elimination of many operations related to quality control→ Increase the motivation of an employee

→ Reduce the overburden of operators from repetitive operations

→ A reduced number of rejects

→ Immediate action when a problem occurs

→ 100% built-in quality control.

→ Less time spent on training workers

→ Promotion of the work improvement-oriented approach

👉 See Also:

Dear Mr. Nikunj, the content is crisp. Would like to comfortably read the same. Would you pl send me a copy of the file. Tks. Gd day. Gopalakrishnan

ReplyDeleteThank you

DeleteDear Nikunj sir,

ReplyDeleteWill you please share Format of Poka yoke ,Error proofing for manufacturing .

Thank you for your input we will do this.

DeleteAbsolutely the best presentation. Very simple to understand. Thanks a lot. Keep up the great work!

ReplyDeleteThank you very much for your kind comment!!!

DeletePoka techniques how with : treat, tolerate, transfer and terminate statements?

ReplyDeleteHi thanks for sharing

Deletehow i can download file

ReplyDeleteIf you are facing any difficulty then you can reach us at contact@nikunjbhoraniya.com

DeletePost a Comment